Confused by the market shift to rebreathers? Sourcing the right components feels like a gamble, risking your inventory and reputation. Let's demystify the tech so you can stock with confidence.

A rebreather recycles a diver's exhaled gas, scrubbing CO2 and adding fresh oxygen. This requires small, specialized high-pressure cylinders for oxygen and a "diluent" gas. For wholesalers, understanding these cylinder specifications—size, pressure, material, and valve type—is the key to serving this growing, high-value market.

Over the years, I've spoken with hundreds of buyers just like you. They see the trend towards rebreathers but hesitate. They have questions about the technology, the market, and most importantly, the specific hardware they need to stock. My goal here is to answer those questions directly. I want to give you the information I share with my best clients, so you can make smart decisions for your business. Let's break it all down, starting with the basics.

What is a Closed-Circuit Rebreather (CCR) and how does it differ from traditional open-circuit scuba?

Customers ask about "no bubbles" diving, but the technical details can be confusing. You risk sounding uninformed if you can't explain the core difference between the two main types of scuba systems.

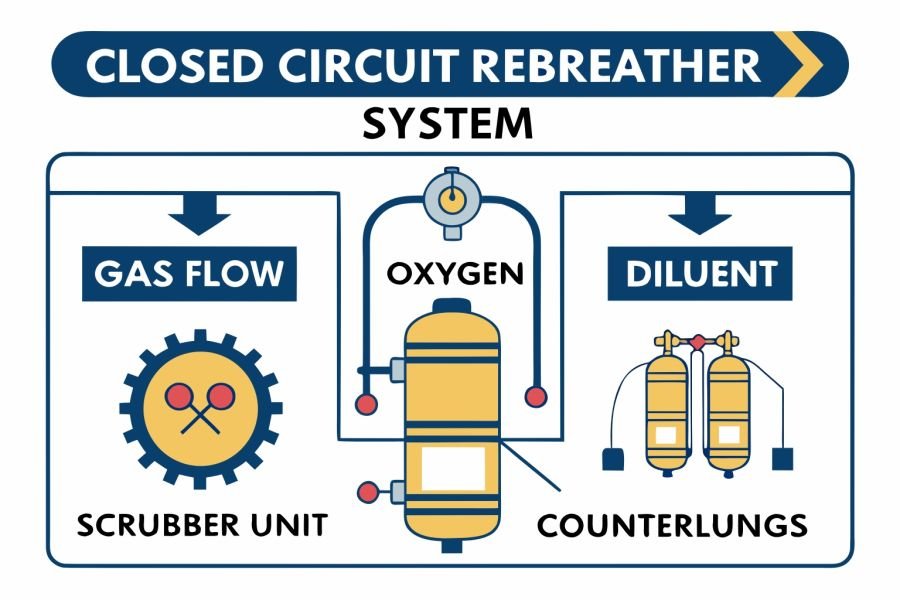

Traditional scuba is "open-circuit": you inhale from the tank and exhale all gas into the water as bubbles. A Closed-Circuit Rebreather (CCR) is different. It recycles your breath, removes the carbon dioxide, and adds back just enough oxygen for you to breathe safely.

I find it helps to think of it in terms of efficiency. When I first started in this industry, everything was about standard open-circuit tanks. It's a brilliant, simple system. But it's also wasteful. With every breath you exhale, you dump valuable gas, and most of the oxygen in it, into the ocean. This is what limits your time underwater. A rebreather is designed to solve that exact problem. It’s a closed loop. It’s all about conservation and efficiency.

Open-Circuit: Simple but Inefficient

With standard scuba gear, the process is straightforward. A diver inhales a breathing gas (like air or nitrox) from a high-pressure cylinder through a regulator. When they exhale, that used gas is vented directly into the water, creating the iconic bubble trail. It’s a beautifully simple and mechanically reliable system, which is why it's perfect for most recreational diving. The downside is that the diver’s body only uses a small fraction of the oxygen in the inhaled gas. The rest is wasted, which is why a standard dive rarely lasts more than an hour.

Closed-Circuit: Complex but Efficient

A rebreather works completely differently. When the diver exhales, the gas goes into a flexible bag called a counter-lung, not into the water. From there, the gas is pushed through a chemical "scrubber" that removes the carbon dioxide (CO2). The system's oxygen sensors then analyze the remaining gas. If the oxygen level is too low, a valve injects a tiny bit of pure oxygen from a small, dedicated cylinder. This revitalized gas then cycles back to the diver to be breathed again. This process explains the key benefits: incredibly long dive times, silent operation, and an optimal breathing gas at any depth. This is why my most demanding clients—technical explorers and professional photographers—have all moved to rebreathers.

What are the specific gas cylinder requirements for rebreather diving systems?

A rebreather order comes in, but they need two small, oddly-sized cylinders. Ordering the wrong specifications means dealing with costly returns, delaying sales, and frustrating a valuable customer. Let's clarify exactly what they need.

Rebreathers require a set of two, or sometimes three, small high-pressure cylinders. Typically, you need one 2-liter or 3-liter cylinder for pure oxygen and another identical cylinder for a "diluent" gas, like air or trimix. These are much smaller than standard scuba tanks.

The most common mistake I see new wholesalers make is trying to apply open-circuit logic to rebreather cylinders. They are not interchangeable. The size, pressure rating, and even the valve threads are often different. A rebreather is a balanced system, and the cylinders are a critical part of that balance. As a manufacturer, we get very specific orders for these tanks, and precision is everything. A client like Juan, who is developing his own hydrogen storage systems in the USA, needs exact specifications. Rebreather divers are just as demanding.

The Oxygen (O2) Cylinder

This is the most critical part of the life-support system. This cylinder holds 100% pure oxygen. Its job is to inject just enough O2 into the breathing loop to replace what the diver’s body metabolizes. Because it only needs to add a tiny amount of gas with each breath, the cylinder can be small, usually 2L or 3L. To maximize the gas supply, these cylinders are almost always rated for high pressure, typically 200 to 300 bar (3000 to 4500 psi).

The Diluent Cylinder

The diluent cylinder serves two purposes. Its primary job is to add gas to the breathing loop to compensate for compression as the diver descends. This "diluent" gas is usually air, but for deeper dives, it can be trimix or heliox. Its secondary, and equally important, job is to serve as an emergency bailout gas supply. If the rebreather fails, the diver can switch to breathing from the diluent cylinder in an open-circuit fashion. For this reason, its size and pressure rating typically match the oxygen cylinder to keep the whole diving unit balanced and streamlined.

| Feature | Standard Scuba Cylinder | Rebreather Cylinder Set |

|---|---|---|

| Typical Size | 11.1 Liters (AL80) | 2 to 3 Liters each |

| Quantity | One primary cylinder | Set of two (O2 and Diluent) |

| Typical Gas | Air or Nitrox | 100% Oxygen & Air/Trimix |

| Primary Function | Sole source of all breathing gas | O2 injection & loop volume/bailout |

Why are more technical divers and rental businesses choosing rebreathers?

You see the rebreather trend growing but might wonder if it's just a temporary niche. Ignoring this fundamental shift in diving could mean losing your most valuable, high-spending customers to competitors who are already adapting.

Divers choose rebreathers for three main reasons: significantly longer bottom times, silent operation for close wildlife encounters, and warmer, moist breathing gas. For businesses, this translates into a premium service offering that attracts serious, dedicated divers who spend more.

This isn't just about a new piece of gear; it's about enabling a completely new kind of diving experience. A few years ago, I visited a client in the Middle East who runs a high-end dive charter. He told me that offering rebreather support was the single best business decision he ever made. His clients weren't asking for cheaper dives; they were asking for better, longer, and more unique dives. Rebreathers were the answer, and being able to supply the correct cylinders and gas fills made him the go-to operator in his region.

For the Diver: The Ultimate Experience

The benefits for the end-user are undeniable. First, longer dives. Instead of the typical 45-60 minute dive on an open-circuit tank, a rebreather can offer three, four, or even more hours underwater. This is essential for deep wreck exploration or penetrating complex cave systems. Second, silence. The lack of noisy bubbles is a game-changer for underwater photographers and marine biologists who want to get close to shy wildlife. Third, comfort. The chemical reaction in the CO2 scrubber warms the gas, and because the breath is recycled, it stays humid. This warm, moist gas is far more comfortable to breathe than the cold, dry air from a standard tank and helps reduce dehydration and fatigue on long dives.

For the Business: A High-Value Market

For a wholesaler or dive shop owner, this all points to a clear business opportunity. Rebreather divers are not casual, once-a-year tourists. They are deeply committed to the sport. They invest thousands of dollars in equipment, training, and travel. They are exactly the type of customer you want. By stocking the necessary equipment, especially the specialized cylinders, you position your business as a serious, expert-level supplier. You become a hub for the local technical diving community, which leads to consistent sales of hardware, gas fills, scrubber material, and other consumables. It's a long-term relationship, not a one-time transaction.

What quality and safety standards are critical when sourcing rebreather cylinders?

A cheap, uncertified cylinder looks tempting on a price sheet. But a failure in a life-support system could be catastrophic for the user and legally devastating for your business. You simply cannot afford to take shortcuts on this kind of equipment.

You must demand cylinders that meet international standards like ISO 7866 for aluminum or ISO 11119 for composite. Also, look for DOT (USA) or TC (Canada) approvals if you sell in North America. Ensure the manufacturer has a proven quality control system and provides full traceability for every unit.

This is a topic I discuss every single day. A buyer will ask for a price, and I will always respond by asking what certifications they require for their market. Quality isn't just a feature; it's a non-negotiable requirement. When your customer is 100 meters underwater, their life depends on the integrity of the cylinder you sold them. I take that responsibility personally, and as a reseller, you should too.

Decoding the Markings

Cylinder markings can look like a secret code, but they tell a critical story. For cylinders sold globally, you want to see an ISO number. This proves it was manufactured to a modern, globally recognized standard. For North American clients, a DOT (Department of Transportation) or TC (Transport Canada) stamp is legally required. For any business like David's in Australia that might re-export to Europe, the Pi (π) mark is essential. Other key markings include the working pressure (WP), test pressure (TP), and the manufacturing date. A cylinder without these clear, professional markings is a huge red flag.

Beyond the Certificate: The Manufacturer's Process

A paper certificate is one thing; a culture of quality is another. I always encourage my clients to ask about the manufacturing process. How do they test their raw materials? Do they perform hydrostatic testing on every cylinder? Do they perform batch destruction tests to ensure strength? A good factory will welcome these questions. At our facility, we have five separate production lines, and each one has multiple quality control stations. We can trace every single cylinder from the initial block of aluminum to the final pressure test. This is the only way to ensure safety. You are not just buying a cylinder; you are buying peace of mind for yourself and your customers.

Should you stock aluminum or carbon fiber cylinders for rebreather divers?

Your customers are asking for lighter gear, but carbon fiber cylinders come with a higher price tag. Stocking the wrong material for your specific market means tying up cash in products that don't move.

Stock both, but understand their distinct roles. Aluminum 6061 cylinders are the durable, cost-effective workhorse for most local divers and rental programs. Carbon fiber composite cylinders are the premium, lightweight option for traveling divers or those needing to minimize weight.

This is a classic business decision: do you serve the bulk of the market or the high-end niche? My answer is always, "Why not both?" The key is to manage your inventory intelligently. You don't need equal amounts of each. You need to stock according to their purpose and the type of customer you serve most often. For most wholesalers, the bulk of their rebreather cylinder sales will be aluminum, with carbon fiber serving as a high-margin specialty item.

The Case for Aluminum (AL)

Aluminum is the backbone of the diving industry for a reason. It is incredibly tough, resistant to the bumps and scrapes of daily use, and very affordable. It's the perfect choice for dive center rental fleets and for local divers who aren't concerned with a few extra kilograms of weight. For a business owner like David, having a reliable stock of 2L and 3L aluminum rebreather cylinders that meet local standards is a safe and consistently profitable strategy. They are the dependable workhorses of the rebreather world.

The Premium Niche for Carbon Fiber (CF)

Carbon fiber is all about one thing: weight reduction. A carbon fiber cylinder can be less than half the weight of its aluminum counterpart. For a diver who flies frequently with their gear, this is a massive advantage that saves them on excess baggage fees. It’s also a huge benefit for technical divers who have long walks to remote dive sites. While the initial cost is higher, you can easily market it as a premium upgrade. The diver who is already spending over $10,000 on a rebreather unit often won't hesitate to spend a bit more for the lightest possible components.

| Feature | Aluminum Cylinders | Carbon Fiber Cylinders |

|---|---|---|

| Weight | Heavier | Significantly Lighter |

| Cost | Lower | Higher |

| Durability | Very high resistance to impacts | Needs more care to avoid surface damage |

| Buoyancy | More negatively buoyant | More neutrally buoyant |

| Best For | Rental fleets, local divers, budget-conscious buyers | Traveling divers, technical divers needing minimal weight |

How can you partner with a manufacturer to ensure a reliable supply of rebreather tanks?

You found a supplier, but communication is slow and lead times are unpredictable. This uncertainty creates stockouts and frustrates your best customers, directly hurting your bottom line and causing you constant stress.

A true partner-manufacturer offers more than just a product. Look for one with direct communication, transparent production schedules, and a commitment to understanding your business needs. They should act as an extension of your purchasing team, ensuring you get the right product, on time.

This is the biggest complaint I hear from buyers like David and Juan. They tell me stories about sending emails that go unanswered for days, or getting vague promises about lead times that are never met. A factory that cannot communicate effectively cannot be a reliable partner. The relationship between a manufacturer and a wholesaler has to be built on trust and clear information. Your supplier's performance directly impacts your reputation.

Step 1: Evaluate Their Communication

Before you even discuss price, test their responsiveness. Send a detailed technical question via email. How quickly do they reply? Is the answer clear, helpful, and written by someone who understands the product, or is it a generic "we will check"? When I started Snowrain, I made a personal commitment to answer every client inquiry within 24 hours. A good supplier respects your time. They must have sales and engineering staff who can communicate clearly and directly.

Step 2: Inquire About Production and Lead Time

Ask direct questions about their factory. "What is your production capacity?" "What is your current, real-world lead time for an order of 500 rebreather cylinders?" A reliable partner will give you a confident, honest answer. Vague responses like "soon" or "we are busy" are major red flags. Because we operate five distinct production lines, we have the flexibility to manage large and small orders simultaneously and can give our clients very predictable delivery windows.

Step 3: Discuss Partnership and Support

Does the manufacturer see you as a number or as a partner? A true partner is invested in your success. Ask them about support for customization. Can they provide cylinders in your company's colors? Can they apply your logo? Can they help you configure cylinders with specific valves for your market? The willingness to work with you on these details shows that they are building a long-term relationship, not just making a single sale. This is the core of our business model and what separates a simple supplier from a true supply chain partner.

What future trends in rebreather technology should your business be prepared for?

The diving market is always changing. Technology that is state-of-the-art today can become standard tomorrow. If you're not looking ahead and anticipating these shifts, you risk getting stuck with inventory that nobody wants.

The future of rebreathers is lighter, smarter, and more integrated. Expect to see a greater demand for lightweight carbon fiber cylinders, electronics with advanced monitoring, and systems that are more user-friendly and accessible to the broader sport diving community.

Staying ahead of the curve is critical for a wholesaler. It allows you to guide your own customers and position yourself as a market leader. I spend a lot of time talking to system designers and industry leaders to understand where the technology is going. Three clear trends are emerging that will directly impact the cylinders you need to stock.

Lighter Materials Will Become Standard

The demand for lighter equipment is relentless. As manufacturing technology improves, the production cost of carbon fiber composite cylinders will continue to fall. This will make them more accessible to a wider range of divers. I am already seeing this in my order books; the ratio of carbon fiber to aluminum inquiries is increasing every year. Wholesalers should plan to gradually increase their inventory of premium lightweight options to meet this growing demand.

Smarter, Connected Systems

The next generation of rebreathers will feature heavily integrated electronics. Think of dive computers that don't just monitor the diver, but that actively monitor and control the rebreather itself. They will provide real-time data on scrubber life, oxygen consumption, and system diagnostics, all logged and accessible via Bluetooth. While you may only sell the cylinders, understanding how they fit into this electronic ecosystem will be vital for providing expert advice to your customers.

The Rise of the "Recreational Rebreather"

The biggest potential change is the simplification of rebreathers for a more mainstream audience. Major manufacturers are working hard to create "turn-key" systems that are easier to learn and safer to use. This could open up the rebreather experience beyond the technical elite to the much larger recreational diving market. Businesses that are already known as experts in rebreather hardware, including having a reliable supply of the correct cylinders, will be in the best possible position to capture this new wave of customers.

Conclusion

Understanding rebreather systems is no longer optional for a serious dive equipment business. By focusing on quality-certified cylinders, building strong manufacturer partnerships, and anticipating future trends, you secure your position as an expert.