An improperly cleaned scuba tank is a hidden danger. This risk threatens not only your divers but your entire business reputation. Understanding professional O2 cleaning is the key to safety.

Professional oxygen cleaning is a detailed process using special cleaners and inspection tools to remove all hydrocarbon contaminants. These contaminants can ignite in a high-pressure oxygen environment. This makes O2 cleaning absolutely essential for any tank used with enriched air nitrox (EANx) blends over 40%.

As a cylinder manufacturer, I've dedicated my career to the highest standards of safety. I've seen firsthand how crucial small details are. The process of preparing a cylinder for oxygen service is something we take very seriously, because we know our partners' businesses and their customers' lives depend on it. It’s more than just a cleaning process; it's a foundational component of diver safety and business integrity. Let’s walk through what every professional in this industry needs to know about this critical task.

Why is professional oxygen cleaning a non-negotiable for dive cylinders used with Enriched Air Nitrox?

You trust your equipment to be safe for every fill. But a tiny, unseen amount of contamination in a tank can lead to a catastrophic failure. Knowing exactly why oxygen cleaning is vital is the first step in protecting your customers, your equipment, and your business.

It's non-negotiable because common hydrocarbon contaminants, like oils from a compressor, can spontaneously ignite in the oxygen-rich, high-pressure environment of a scuba tank. This can cause a fire or explosion, making professional cleaning a critical and mandatory safety procedure.

The Simple Chemistry of an Oxygen Fire

You might remember the "fire triangle" from a basic safety course: fuel, heat, and oxygen. In a scuba tank, all three can be present.

- Oxygen: Enriched Air Nitrox (EANx) obviously contains more oxygen than standard air. The higher the percentage, the higher the risk.

- Heat: The act of rapidly pressurizing a cylinder during a fill generates significant heat. This is a normal part of physics.

- Fuel: This is the dangerous variable. The "fuel" is any hydrocarbon substance. This could be oil particles from a poorly maintained compressor, residue from improper cleaning agents, or even oils from human skin.

When these three elements combine inside a tank, the result can be a violent fire. As a manufacturer, I design tanks to withstand immense pressure, but not an internal combustion event. That is why removing the fuel component is the only way to ensure safety.

Beyond the "40% Rule"

The common rule of thumb in the diving industry is that any cylinder used with a gas mix containing over 40% oxygen must be oxygen clean. While this is a widely accepted minimum standard, many safety-conscious organizations and training agencies recommend a more conservative approach. The US Navy, for example, requires cleaning for anything over 25% oxygen. At my factory, we recommend that any tank dedicated to any EANx use be kept oxygen clean. This removes any ambiguity and builds a robust culture of safety in your operation. It’s the professional standard.

Protecting Your Business and Reputation

An equipment failure linked to improper cleaning is not just an accident; it's a major liability. For a business owner like David, this means facing potential lawsuits, insurance claims, and irreparable damage to the trust you've built with your customers. Word travels fast in the diving community. A single safety incident can undo years of hard work. Therefore, enforcing strict O2 cleaning protocols is a powerful investment in your business's long-term health and reputation.

What are the official industry standards and regulations that every dive business must follow?

You hear a lot of different opinions and "shop rules" about tank servicing. Following the wrong advice is not only dangerous, but it can also put you in a state of non-compliance. Let's clarify the real industry standards that should guide your operations.

Key standards are published by organizations like the Compressed Gas Association (CGA) and the Divers Alert Network (DAN). The benchmark document is CGA G-4.1, "Cleaning Equipment for Oxygen Service." Following these established, written protocols is the mark of a truly professional operation.

Key Organizations and Their Roles

Understanding the organizations that set the standards helps you appreciate their importance. These aren't arbitrary rules; they are guidelines developed by experts over decades.

| Organization | Role in Oxygen Cleaning | Why It Matters to Your Business |

|---|---|---|

| CGA (Compressed Gas Association) | Publishes detailed technical standards for the entire industrial gas industry, including scuba. CGA G-4.1 is the definitive guide. | Following CGA standards demonstrates professional diligence and is often considered the legal standard of care in North America. |

| DAN (Divers Alert Network) | A dive safety organization that provides research, education, and resources. They translate technical standards into practical advice for divers and shops. | DAN's recommendations carry significant weight in the recreational diving community and with insurance providers. |

| ISO (International Organization for Standardization) | Develops global standards for many industries, including manufacturing. ISO 9001, for example, relates to quality management systems. | A manufacturer with ISO certification, like my facility, demonstrates a commitment to repeatable, high-quality processes. |

The Importance of Documentation

If a procedure isn't documented, it's as if it never happened. This is especially true for safety-critical tasks. A professional dive shop must maintain meticulous records for every cylinder it services. This documentation is your proof of diligence. After a cylinder is O2 cleaned, it should be marked with a sticker or tag that is easily visible. This tag provides clear information to the filler and the diver.

A proper record should include:

- The date of the oxygen cleaning service.

- The name or initials of the certified technician who performed the work.

- A clear statement like "Oxygen Clean" or "Prepared for Oxygen Service."

- The date the next inspection is due.

This level of documentation protects you, your staff, and your customers.

What is the correct step-by-step process for cleaning a scuba tank for dedicated oxygen service?

"Cleaning a tank" might sound simple, like washing a bottle. But a single shortcut or a missed step in the professional process can render the entire effort useless. Here is the reliable, multi-stage process that every certified technician follows.

The process is meticulous. It requires complete disassembly of the tank and valve, a degreasing bath with an oxygen-compatible cleaner, a thorough rinse with pure water, and drying with hot, oil-free air. Finally, inspection and reassembly must occur in a dedicated clean environment.

Step 1: Disassembly and Pre-Cleaning

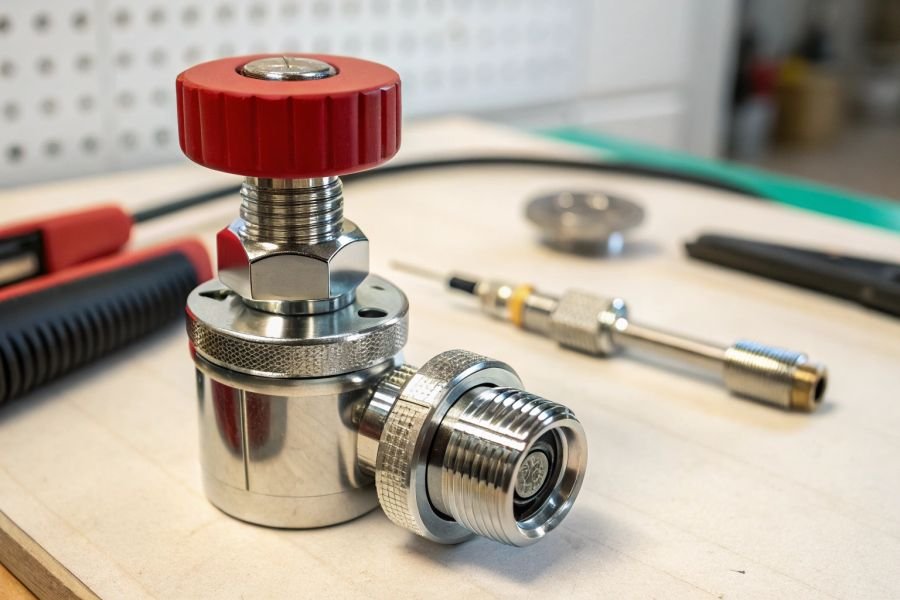

The process begins by safely depressurizing and removing the cylinder valve. This is the only way to get full access to the interior of the tank. The valve itself is a complex piece of equipment and must be completely disassembled. Every single component—the stem, the seat, all O-rings—is separated. Once open, the technician performs an initial visual inspection of the cylinder's interior. Any large particles or visible debris are carefully removed. This "pre-cleaning" step ensures that the primary cleaning solution can work effectively on the microscopic contaminants it's designed to target. It's a preparatory stage that sets the foundation for the critical steps to follow.

Step 2: The Degreasing and Rinsing Cycle

This is the core of the process. The cylinder and all valve components are submerged in a specially formulated, oxygen-compatible degreasing solution. These are typically strong alkaline detergents that are proven to break down and remove hydrocarbons without leaving a residue of their own. The cylinder may be agitated or tumbled to ensure the cleaner reaches every part of the interior surface. After the wash, rinsing is just as important. The cylinder must be rinsed multiple times with clean, pure water until every trace of the cleaning agent is gone. Any remaining detergent could become a contaminant itself.

Step 3: Drying, Final Inspection, and Reassembly

Moisture is also a contaminant and can promote corrosion. The cylinder and its components must be dried completely using a stream of heated, oil-free air. A standard shop compressor cannot be used for this, as its air contains oil. Once dry, the most critical inspection happens. The technician uses a high-intensity, ultraviolet (UV) or black light to inspect the interior. Hydrocarbons fluoresce brightly under UV light, making even the tiniest remaining trace visible. Only after the cylinder passes this inspection can reassembly begin. New, oxygen-compatible O-rings and seats are installed using special O2-compatible lubricants. The valve is re-installed to the correct torque, and the cylinder is sealed to prevent re-contamination.

Does the cleaning process differ between aluminum and carbon fiber dive cylinders?

You likely stock both traditional aluminum tanks and modern, lightweight carbon fiber cylinders. It’s a logical question to ask if these different materials require different care. A good technician knows that while the goal is the same, the method must respect the material.

The core principle—the complete removal of hydrocarbons—is identical for both. However, the specific cleaning agents and handling methods must be appropriate for the material. Using a chemical that is safe for aluminum could potentially damage the resin matrix of a carbon fiber cylinder.

Material-Specific Considerations

An aluminum cylinder is a single piece of extruded metal. It is incredibly robust and resistant to a wide range of cleaning chemicals. A carbon fiber cylinder, on the other hand, is a composite structure. It consists of a thin aluminum liner wrapped in carbon fiber and fiberglass, all held together by a special resin. While the internal liner is aluminum, the exterior and the neck area require more careful handling. Harsh chemicals or abrasive methods could compromise the integrity of the resin, which is critical to the cylinder's strength. I've seen cases where improper handling in a service center has damaged the exterior of a perfectly good carbon fiber tank.

Always Follow Manufacturer Recommendations

This is the most important rule. The company that built the cylinder knows its materials best. As a manufacturer, we provide specific guidelines on what cleaning agents and procedures are tested and approved for our cylinders. Ignoring these recommendations can void the cylinder's warranty and, more importantly, create a safety risk. A professional service technician will always consult the manufacturer's documentation before working on a cylinder, especially a composite one. This is why building a relationship with a responsive manufacturer is so important. When you have a question, you need a quick, reliable answer.

| Feature | Aluminum Cylinders | Carbon Fiber Cylinders |

|---|---|---|

| Primary Concern | Complete interior cleaning. | Interior cleaning plus protecting the exterior composite wrap and resin. |

| Approved Cleaners | Wide range of approved alkaline detergents. | Must use cleaners confirmed to be safe for epoxy resins and composites. |

| Handling | Very durable and resistant to scratches. | Must be handled carefully to avoid gouges or impacts to the carbon fiber wrap. |

| Inspection Focus | Internal surfaces and neck threads. | Internal surfaces, neck threads, and a thorough inspection of the external wrap for any signs of damage. |

How can you verify that a new scuba tank is truly "oxygen clean" directly from the manufacturer?

A supplier tells you their new cylinders are "O2 clean." But in a business where safety is paramount, you can't just take their word for it. You need proof. As a buyer, you have the right to know and verify the condition of the products you receive.

Look for clear, physical evidence. A genuinely O2-clean tank from a manufacturer will be sealed at the valve opening with a tamper-evident cap or sticker. It must also be accompanied by official documentation or a certificate stating its fitness for oxygen service.

The Importance of the Factory Seal

When a cylinder leaves my production line ready for oxygen service, it's not just clean—it's sterile on the inside. The final step we take is to seal the valve opening. This is usually done with a distinctive, colored plastic cap or a special sticker that reads "Oxygen Clean." This seal is your guarantee. It proves that no contaminants—dust, moisture, or oil particles—have entered the cylinder during shipping and storage. If you receive a tank that is supposed to be O2 clean but the seal is broken or missing, you cannot trust its condition. It must be treated as a standard air tank and professionally cleaned before being used for EANx.

What to Look For in the Documentation

The physical seal should be backed up by paperwork. A reliable manufacturer will include a certificate or a clear statement on the packing slip or invoice. This isn't just a marketing claim; it's a formal declaration of compliance. This document should state that the cylinder (often identified by its serial number) has been prepared for oxygen service in accordance with a specific industry standard, such as "CGA G-4.1." This documentation is crucial for your records. It shows your due diligence in sourcing safe, high-quality equipment for your customers.

At my factory, we made the decision years ago that this was not an optional extra. For us, it's a fundamental part of our quality promise. Every cylinder we produce that is intended for use with EANx is professionally cleaned, inspected under UV light, and sealed before it ever leaves our facility. We include the certification so our partners, like David, can have complete peace of mind from the moment they open the box.

What key questions should you ask a cylinder supplier to guarantee their tanks meet your quality and safety requirements?

Choosing a cylinder supplier is a long-term business decision. A bad choice can lead to endless problems with quality, delivery, and communication. Asking tough, specific questions upfront is the best way to protect your business and find a true partner.

Go beyond price. Ask about their specific O2 cleaning standards (do they follow CGA G-4.1?). Inquire about their packaging methods. And most importantly, ask for copies of their quality certifications, like ISO 9001, to prove they have a robust system in place.

Go Deeper Than Just Cleaning

A supplier's commitment to quality should be evident in their entire manufacturing process. Don't be afraid to ask detailed questions.

- "What is your quality control process for raw materials?"

- "Can you provide batch traceability? If I have an issue with a cylinder, can you trace it back to its specific production run?"

- "What international certifications does your factory hold (e.g., ISO, DOT, TC, CE)?"

The answers to these questions reveal whether you're dealing with a simple trader or a dedicated, professional manufacturer. A good supplier will be proud to share this information. As I've always told my team, our certifications are not just pieces of paper; they are a promise to our customers.

Communication Is a Feature

I know from talking to hundreds of buyers that one of the biggest frustrations is poor communication. Inefficient replies and vague answers are huge red flags. Before you place an order, test their communication.

- "What is your standard response time for emails?"

- "Will I have a dedicated sales representative?"

- "What is your process for providing updates on production and shipping?"

Slow communication before a sale will only get worse after they have your money. A professional partner will respond promptly and clearly, just like you expect from your own team.

A Partnership for Success

Ultimately, you are not just buying steel or aluminum cylinders. You are investing in a critical piece of safety equipment and entering a business relationship. The right supplier acts as a partner who is invested in your success. They understand that the quality of their product directly impacts your reputation. When you ask these tough questions, you're not being difficult; you're being a smart business owner. You are laying the groundwork for a reliable, long-term partnership that you can build your business on.

Conclusion

Professional O2 cleaning is not just a technical task. It is a fundamental part of your commitment to safety, quality, and the long-term success of your diving business.